on video Star Delta Starter Explained - Principle of Operation

Traditionally, in many supply regions, it has been necessary to install a reduced voltage starter on all motors above 5 HP (4 KW). The star/delta (or star/delta) starter is one of the least expensive reduced voltage electromechanical starters that can be applied.

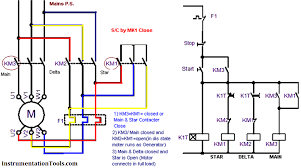

The Star/Delta starter is made from three contactors, a timer and a thermal overload. Contactors are smaller than the single contactor used in a Direct on Line starter because they only control the winding currents. The currents in the winding are 1/root 3 (58%) of the current in the line.

There are two contactors that are close during run, often referred to as the main contractor and the delta contactor. These are rated AC3 at 58% of motor rated current. The third contactor is the star contactor and only carries star current when the motor is star connected.

The star current is equal to one third of the delta current. This contactor can therefore be rated AC3 at one third (33%) of the rated motor power.

Traditionally, in many supply regions, it has been necessary to install a reduced voltage starter on all motors above 5 HP (4 KW). The star/delta (or star/delta) starter is one of the least expensive reduced voltage electromechanical starters that can be applied.

The Star/Delta starter is made from three contactors, a timer and a thermal overload. Contactors are smaller than the single contactor used in a Direct on Line starter because they only control the winding currents. The currents in the winding are 1/root 3 (58%) of the current in the line.

There are two contactors that are close during run, often referred to as the main contractor and the delta contactor. These are rated AC3 at 58% of motor rated current. The third contactor is the star contactor and only carries star current when the motor is star connected.

The star current is equal to one third of the delta current. This contactor can therefore be rated AC3 at one third (33%) of the rated motor power.

![Transformateurs triphasés [ l'étoile - triangle]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEgfrGJWOWiKdh5DvfZk3WZSqBi10gXs2khB0NJtJhI44hX7zjU1gkqKTpeTDbpmMEzgZXpfdzdyIDt6xOo7P1bZbYfm5_Jb4LQ8TZFzybV_heL92b5TI7yk1noqyINhckwGqU4dR70A8sDd/s72-c/triangle-etoile.png)

No comments