on video Power Transmission in Mechanical Engineering

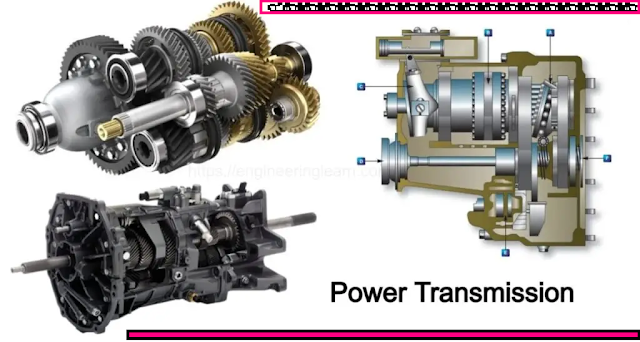

Power Transmission in Mechanical Engineering:- Power transmission is an engg. Method which is based on the principle of supplying the machines & the working part of the machines in terms of energy configurations, speed of movement, forms of movement. Generally there are 4 types of transmission all of which are currently in use are as follows:

Mechanical transmission

Pneumatic transmission

Electric transmission

Hydraulic transmission

Drives/conveyors or transmissions can be used to move part of the machines. All machines need movement such as pumps, fans, conveyor belts, etc. There are several training systems.

Power transmission types

1. Mechanical transmission

A. Mechanical drives

Mechanical drives are one of the oldest technologies that are consistent in the industry. Both power and motion are initiated by drive motors such as belts, chains, or gears. The power is transmitted by the rotation movement to another rotation movement.

B. Belt drives

Belt drives The main purpose of belt drives is to transfer power between two parallel axes by a belt. Pulleys are installed on these axles so that the belts move freely on them. When the axle pulleys have the same diameter, they will rotate at the same speed. If one of the axles is different from the other, the speed will be effectively increased or decreased. Drive belt pulleys generally rotate in the same direction.

Advantage: simple structure, long service life, capable of short-distance transmission, transmission ratio is accurate.

Disadvantages: high accuracy requires high manufacturing cost.

2. Electric transmission

It uses the electric motor to convert electrical energy into mechanical energy for the operation of various types of production machinery. The electric motor is used as the power source with high precision, and the ball screw and timing are a simple and efficient transmission mechanism. The engine providing a repeatability error is 0.01%.

Energy saving: – the energy released by the operating cycle in the working phase is reversed, which reduces operating costs.

Noise Reduction: - The operating noise value of the product is less than 70 decibels, which is 2/3 of the value of the hydraulic drive injection molding machine.

Precise control:– precise control according to set parameters, providing the necessary support for high-precision sensors, measuring devices, computer technology.

3. Pneumatic transmission

Uses gas or fluid pressure by compressed gas (used as working fluid). Pneumatic system in which the power is supplied to the compressed gas through the pipe equipped with a control valve to the pneumatic actuator, the actuators transform the pressure of the compressed gas into work of mechanical energy.

Advantages: low working pressure, small gas loss provides the advantage in medium-distance supply and transportation, safe and explosion-proof.

Cons: Air pressure is low and requires compressor air supply which adds to the cost of the equipment.

4. Hydraulic transmission

the hydraulic transmission uses a liquid as the working medium to transfer energy and control. Equipment with hydraulic technology is safe and reliable. It transmits energy through liquid kinetic energy. The turbine converts rotational speed and input torque. The input and output shafts are connected to the working medium by a liquid.

Components:– Hydraulic Pump, Hydraulic Control Valve and Actuator, Hydraulic Assembly.

Application:– automobiles, construction machinery, oil drilling machinery.

Power Transmission in Mechanical Engineering:- Power transmission is an engg. Method which is based on the principle of supplying the machines & the working part of the machines in terms of energy configurations, speed of movement, forms of movement. Generally there are 4 types of transmission all of which are currently in use are as follows:

Mechanical transmission

Pneumatic transmission

Electric transmission

Hydraulic transmission

Drives/conveyors or transmissions can be used to move part of the machines. All machines need movement such as pumps, fans, conveyor belts, etc. There are several training systems.

Power transmission types

1. Mechanical transmission

A. Mechanical drives

Mechanical drives are one of the oldest technologies that are consistent in the industry. Both power and motion are initiated by drive motors such as belts, chains, or gears. The power is transmitted by the rotation movement to another rotation movement.

B. Belt drives

Belt drives The main purpose of belt drives is to transfer power between two parallel axes by a belt. Pulleys are installed on these axles so that the belts move freely on them. When the axle pulleys have the same diameter, they will rotate at the same speed. If one of the axles is different from the other, the speed will be effectively increased or decreased. Drive belt pulleys generally rotate in the same direction.

Advantage: simple structure, long service life, capable of short-distance transmission, transmission ratio is accurate.

Disadvantages: high accuracy requires high manufacturing cost.

2. Electric transmission

It uses the electric motor to convert electrical energy into mechanical energy for the operation of various types of production machinery. The electric motor is used as the power source with high precision, and the ball screw and timing are a simple and efficient transmission mechanism. The engine providing a repeatability error is 0.01%.

Energy saving: – the energy released by the operating cycle in the working phase is reversed, which reduces operating costs.

Noise Reduction: - The operating noise value of the product is less than 70 decibels, which is 2/3 of the value of the hydraulic drive injection molding machine.

Precise control:– precise control according to set parameters, providing the necessary support for high-precision sensors, measuring devices, computer technology.

3. Pneumatic transmission

Uses gas or fluid pressure by compressed gas (used as working fluid). Pneumatic system in which the power is supplied to the compressed gas through the pipe equipped with a control valve to the pneumatic actuator, the actuators transform the pressure of the compressed gas into work of mechanical energy.

Advantages: low working pressure, small gas loss provides the advantage in medium-distance supply and transportation, safe and explosion-proof.

Cons: Air pressure is low and requires compressor air supply which adds to the cost of the equipment.

4. Hydraulic transmission

the hydraulic transmission uses a liquid as the working medium to transfer energy and control. Equipment with hydraulic technology is safe and reliable. It transmits energy through liquid kinetic energy. The turbine converts rotational speed and input torque. The input and output shafts are connected to the working medium by a liquid.

Components:– Hydraulic Pump, Hydraulic Control Valve and Actuator, Hydraulic Assembly.

Application:– automobiles, construction machinery, oil drilling machinery.

Power Transmission in Mechanical Engineering:- Power transmission is an engg. Method which is based on the principle of supplying the machines & the working part of the machines in terms of energy configurations, speed of movement, forms of movement. Generally there are 4 types of transmission all of which are currently in use are as follows:

Mechanical transmission

Pneumatic transmission

Electric transmission

Hydraulic transmission

Drives/conveyors or transmissions can be used to move part of the machines. All machines need movement such as pumps, fans, conveyor belts, etc. There are several training systems.

Power transmission types

1. Mechanical transmission

A. Mechanical drives

Mechanical drives are one of the oldest technologies that are consistent in the industry. Both power and motion are initiated by drive motors such as belts, chains, or gears. The power is transmitted by the rotation movement to another rotation movement.

B. Belt drives

Belt drives The main purpose of belt drives is to transfer power between two parallel axes by a belt. Pulleys are installed on these axles so that the belts move freely on them. When the axle pulleys have the same diameter, they will rotate at the same speed. If one of the axles is different from the other, the speed will be effectively increased or decreased. Drive belt pulleys generally rotate in the same direction.

Advantage: simple structure, long service life, capable of short-distance transmission, transmission ratio is accurate.

Disadvantages: high accuracy requires high manufacturing cost.

2. Electric transmission

It uses the electric motor to convert electrical energy into mechanical energy for the operation of various types of production machinery. The electric motor is used as the power source with high precision, and the ball screw and timing are a simple and efficient transmission mechanism. The engine providing a repeatability error is 0.01%.

Energy saving: – the energy released by the operating cycle in the working phase is reversed, which reduces operating costs.

Noise Reduction: - The operating noise value of the product is less than 70 decibels, which is 2/3 of the value of the hydraulic drive injection molding machine.

Precise control:– precise control according to set parameters, providing the necessary support for high-precision sensors, measuring devices, computer technology.

3. Pneumatic transmission

Uses gas or fluid pressure by compressed gas (used as working fluid). Pneumatic system in which the power is supplied to the compressed gas through the pipe equipped with a control valve to the pneumatic actuator, the actuators transform the pressure of the compressed gas into work of mechanical energy.

Advantages: low working pressure, small gas loss provides the advantage in medium-distance supply and transportation, safe and explosion-proof.

Cons: Air pressure is low and requires compressor air supply which adds to the cost of the equipment.

4. Hydraulic transmission

the hydraulic transmission uses a liquid as the working medium to transfer energy and control. Equipment with hydraulic technology is safe and reliable. It transmits energy through liquid kinetic energy. The turbine converts rotational speed and input torque. The input and output shafts are connected to the working medium by a liquid.

Components:– Hydraulic Pump, Hydraulic Control Valve and Actuator, Hydraulic Assembly.

Application:– automobiles, construction machinery, oil drilling machinery.

Power Transmission in Mechanical Engineering:- Power transmission is an engg. Method which is based on the principle of supplying the machines & the working part of the machines in terms of energy configurations, speed of movement, forms of movement. Generally there are 4 types of transmission all of which are currently in use are as follows:

Mechanical transmission

Pneumatic transmission

Electric transmission

Hydraulic transmission

Drives/conveyors or transmissions can be used to move part of the machines. All machines need movement such as pumps, fans, conveyor belts, etc. There are several training systems.

Power transmission types

1. Mechanical transmission

A. Mechanical drives

Mechanical drives are one of the oldest technologies that are consistent in the industry. Both power and motion are initiated by drive motors such as belts, chains, or gears. The power is transmitted by the rotation movement to another rotation movement.

B. Belt drives

Belt drives The main purpose of belt drives is to transfer power between two parallel axes by a belt. Pulleys are installed on these axles so that the belts move freely on them. When the axle pulleys have the same diameter, they will rotate at the same speed. If one of the axles is different from the other, the speed will be effectively increased or decreased. Drive belt pulleys generally rotate in the same direction.

Advantage: simple structure, long service life, capable of short-distance transmission, transmission ratio is accurate.

Disadvantages: high accuracy requires high manufacturing cost.

2. Electric transmission

It uses the electric motor to convert electrical energy into mechanical energy for the operation of various types of production machinery. The electric motor is used as the power source with high precision, and the ball screw and timing are a simple and efficient transmission mechanism. The engine providing a repeatability error is 0.01%.

Energy saving: – the energy released by the operating cycle in the working phase is reversed, which reduces operating costs.

Noise Reduction: - The operating noise value of the product is less than 70 decibels, which is 2/3 of the value of the hydraulic drive injection molding machine.

Precise control:– precise control according to set parameters, providing the necessary support for high-precision sensors, measuring devices, computer technology.

3. Pneumatic transmission

Uses gas or fluid pressure by compressed gas (used as working fluid). Pneumatic system in which the power is supplied to the compressed gas through the pipe equipped with a control valve to the pneumatic actuator, the actuators transform the pressure of the compressed gas into work of mechanical energy.

Advantages: low working pressure, small gas loss provides the advantage in medium-distance supply and transportation, safe and explosion-proof.

Cons: Air pressure is low and requires compressor air supply which adds to the cost of the equipment.

4. Hydraulic transmission

the hydraulic transmission uses a liquid as the working medium to transfer energy and control. Equipment with hydraulic technology is safe and reliable. It transmits energy through liquid kinetic energy. The turbine converts rotational speed and input torque. The input and output shafts are connected to the working medium by a liquid.

Components:– Hydraulic Pump, Hydraulic Control Valve and Actuator, Hydraulic Assembly.

Application:– automobiles, construction machinery, oil drilling machinery.

No comments