on video Programable Logic Controller Basics Explained - automation engineering

What is a PLC?

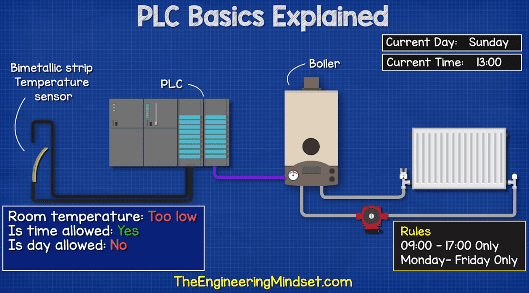

A PLC, or programmable language controller, is a compact industrial computer designed to control system processes from one location. You may have heard about PLCs but haven't fully grasped the concept. PLCs are like the brains of industrial automation equipment. Instead of having several machines or workers managing different systems and equipment, PLC controllers can complete various tasks at once with a built-in I/O module (inputs and outputs). Programmable logic controllers are everywhere and heavily used across many industries. This post will dive into the main components of a PLC, programming languages, types of PLCs, and PLC systems in the future. Traffic light signals are a great example of a PLC application. Instead of having someone reading data and pushing buttons, there is now a PLC system in place to control and monitor this function within one housing unit. If programmable logic controllers are relatively a new concept for you, then it might be hard to imagine the many types of possible PLC applications around you. Other recognizable PLC applications include automatic car washes, elevators, automatic doors, and amusement rides.

of PLCs

To understand the purpose of a PLC, we'll need to go back in time to the 1960s. Picture transistor radios, Barbie dolls, G.I. Joe action figures, and Chevrolet Impalas. Machine processes during this era were controlled through the use of electromechanical relays. We're not talking about a few relays either, these systems took up entire walls. However, the size of the relay-powered machines was not the only disadvantage.

Downsides of relay-powered machines:

Hard-wiring had to be done in a very specific order.

Time-consuming troubleshooting.

Constant troubleshooting due to worn relay contacts.

Strict maintenance schedule.

Large and cumbersome.

Changes involved entire system rewiring.

It wasn't long before engineers began brainstorming solutions to these pain points. With the introduction of computer control in the industrial sector, the first version of the PLC was developed. The invention of the programmable logic controller is attributed to Richard Morley and his company, Bedford and Associates.

What is a PLC?

A PLC, or programmable language controller, is a compact industrial computer designed to control system processes from one location. You may have heard about PLCs but haven't fully grasped the concept. PLCs are like the brains of industrial automation equipment. Instead of having several machines or workers managing different systems and equipment, PLC controllers can complete various tasks at once with a built-in I/O module (inputs and outputs). Programmable logic controllers are everywhere and heavily used across many industries. This post will dive into the main components of a PLC, programming languages, types of PLCs, and PLC systems in the future. Traffic light signals are a great example of a PLC application. Instead of having someone reading data and pushing buttons, there is now a PLC system in place to control and monitor this function within one housing unit. If programmable logic controllers are relatively a new concept for you, then it might be hard to imagine the many types of possible PLC applications around you. Other recognizable PLC applications include automatic car washes, elevators, automatic doors, and amusement rides.

of PLCs

To understand the purpose of a PLC, we'll need to go back in time to the 1960s. Picture transistor radios, Barbie dolls, G.I. Joe action figures, and Chevrolet Impalas. Machine processes during this era were controlled through the use of electromechanical relays. We're not talking about a few relays either, these systems took up entire walls. However, the size of the relay-powered machines was not the only disadvantage.

Downsides of relay-powered machines:

Hard-wiring had to be done in a very specific order.

Time-consuming troubleshooting.

Constant troubleshooting due to worn relay contacts.

Strict maintenance schedule.

Large and cumbersome.

Changes involved entire system rewiring.

It wasn't long before engineers began brainstorming solutions to these pain points. With the introduction of computer control in the industrial sector, the first version of the PLC was developed. The invention of the programmable logic controller is attributed to Richard Morley and his company, Bedford and Associates.

![Transformateurs triphasés [ l'étoile - triangle]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEgfrGJWOWiKdh5DvfZk3WZSqBi10gXs2khB0NJtJhI44hX7zjU1gkqKTpeTDbpmMEzgZXpfdzdyIDt6xOo7P1bZbYfm5_Jb4LQ8TZFzybV_heL92b5TI7yk1noqyINhckwGqU4dR70A8sDd/s72-c/triangle-etoile.png)

No comments