on video Diesel Engine, How it works ?

Have you ever looked at a truck or large piece of machinery and wondered where its power comes from? The answer is simple: diesel engines.

From passenger cars and trucks to railroad locomotives, farming equipment, and even cargo ships, diesel engines power some of the vehicles our world relies on most. Diesel engines are often favored for their efficiency and durability, especially when compared with gasoline engines.

Keep reading to learn all about these incredible engines — what they are, how they work and what diesel technicians need to know to be successful.

What is a diesel engine?

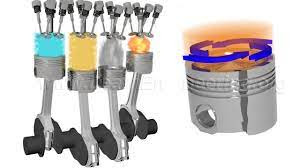

Diesel engines, like gas engines, are internal combustion engines that convert chemical energy into mechanical energy. This process moves pistons up and down inside the cylinders, which then leads to the movement that turns the wheels of a vehicle.

Through a series of small combustion (or explosions), diesel engines convert fuel into energy. They are used in many different types of equipment and vehicles, including:

Passenger cars and trucks

Medium duty trucks

Cruise ships

Cargo ships

Power generators

Locomotives

Farming equipment

Construction equipment

Various industrial applications

There are several reasons diesel engines are chosen over gas engines for certain applications. These include:

Thermal efficiency: Diesel engines are about 20% more thermally efficient than gas engines. Thermal efficiency refers to the expected work from the fuel put into the engine.

Power and torque: An increase in thermal efficiency means diesel engines provide more power and torque. This makes diesel engines ideal for heavy loads.

Lower operating costs: Diesel engines are known for their increased fuel efficiency, which can result in lower operating costs.

Reliability: Compared with gas engines, diesel engines run with fewer revolutions per minute (RPM). This results in less wear and tear on the engine.

Life expectancy: Many people choose diesel engines for their long life cycles. The way diesel engines are built supports this — their castings and cylinder walls are thicker and their oiling system has a higher volume. Most diesel engines have cylinder liners that can be replaced, helping to increase the life of the engine.

Diesel Engine Components

Diesel engines are robust. They are made up of several different parts, and each part must work correctly to power the engine. Below is a breakdown of some of the most important components of these engines.

Fuel System

The fuel system consists of the fuel tank, water separator, feed pump (low-pressure), filter, high-pressure pump, injector nozzle and cylinder. Essentially, the fuel tank stores the fuel, then a low-pressure pump pulls the fuel from the tank through a filter/water separator, then pushes the fuel through another filter. From there, fuel pressure is stepped up via a high-pressure pump, whether it is an injection pump or a unit injector.

Lubrication System

The lubrication system plays an important role in the engine. It reduces wear and tear of rubbing surfaces by placing a film of oil between parts, reduces the power required to overcome friction, and removes heat from the pistons and other parts of the engine. It also separates the cylinders and piston rings.

Air Intake System

In this system, air flows into the cylinder bore through the air cleaner, which prevents dust from entering. The turbocharger compresses air from the air filter, and the intake manifold takes the air from the turbocharger to the inlet port. Finally, the intake valve allows air to pass into the cylinder bore, and a camshaft controls when the valve opens and closes.

Exhaust System

In this system, exhaust gas is passed through the diesel particulate filter, which traps solids in the exhaust stream. These solids, or particles, are carbon and ash. The filter will need to undergo a cleaning process called regeneration periodically to convert the carbon into carbon dioxide through exposure to high temperatures.

The gas then passes through the selective catalyst reduction system, which removes the oxides of nitrogen with the help of diesel exhaust fluid. There is also an exhaust gas recirculation valve, cooler and mixer in this system. All of this equipment is there to reduce harmful emissions.

Cooling System

The cooling system helps maintain proper engine temperature, which allows all of the parts to work correctly. It keeps oil and engine components at the right temperature, which in turn helps protect the cylinder head, cylinders, valves and pistons. There are two different types of cooling used in internal combustion engines: air cooling and water cooling. While gas engines can use either method, diesel engines use water cooling exclusively.

Electrical System

The electrical system is made up of the alternator, starter motor and battery. The starter motor, which is powered by the battery, rotates the flywheel, which rotates the crankshaft. This is what causes the pistons to move in the cylinders. The piston c

Have you ever looked at a truck or large piece of machinery and wondered where its power comes from? The answer is simple: diesel engines.

From passenger cars and trucks to railroad locomotives, farming equipment, and even cargo ships, diesel engines power some of the vehicles our world relies on most. Diesel engines are often favored for their efficiency and durability, especially when compared with gasoline engines.

Keep reading to learn all about these incredible engines — what they are, how they work and what diesel technicians need to know to be successful.

What is a diesel engine?

Diesel engines, like gas engines, are internal combustion engines that convert chemical energy into mechanical energy. This process moves pistons up and down inside the cylinders, which then leads to the movement that turns the wheels of a vehicle.

Through a series of small combustion (or explosions), diesel engines convert fuel into energy. They are used in many different types of equipment and vehicles, including:

Passenger cars and trucks

Medium duty trucks

Cruise ships

Cargo ships

Power generators

Locomotives

Farming equipment

Construction equipment

Various industrial applications

There are several reasons diesel engines are chosen over gas engines for certain applications. These include:

Thermal efficiency: Diesel engines are about 20% more thermally efficient than gas engines. Thermal efficiency refers to the expected work from the fuel put into the engine.

Power and torque: An increase in thermal efficiency means diesel engines provide more power and torque. This makes diesel engines ideal for heavy loads.

Lower operating costs: Diesel engines are known for their increased fuel efficiency, which can result in lower operating costs.

Reliability: Compared with gas engines, diesel engines run with fewer revolutions per minute (RPM). This results in less wear and tear on the engine.

Life expectancy: Many people choose diesel engines for their long life cycles. The way diesel engines are built supports this — their castings and cylinder walls are thicker and their oiling system has a higher volume. Most diesel engines have cylinder liners that can be replaced, helping to increase the life of the engine.

Diesel Engine Components

Diesel engines are robust. They are made up of several different parts, and each part must work correctly to power the engine. Below is a breakdown of some of the most important components of these engines.

Fuel System

The fuel system consists of the fuel tank, water separator, feed pump (low-pressure), filter, high-pressure pump, injector nozzle and cylinder. Essentially, the fuel tank stores the fuel, then a low-pressure pump pulls the fuel from the tank through a filter/water separator, then pushes the fuel through another filter. From there, fuel pressure is stepped up via a high-pressure pump, whether it is an injection pump or a unit injector.

Lubrication System

The lubrication system plays an important role in the engine. It reduces wear and tear of rubbing surfaces by placing a film of oil between parts, reduces the power required to overcome friction, and removes heat from the pistons and other parts of the engine. It also separates the cylinders and piston rings.

Air Intake System

In this system, air flows into the cylinder bore through the air cleaner, which prevents dust from entering. The turbocharger compresses air from the air filter, and the intake manifold takes the air from the turbocharger to the inlet port. Finally, the intake valve allows air to pass into the cylinder bore, and a camshaft controls when the valve opens and closes.

Exhaust System

In this system, exhaust gas is passed through the diesel particulate filter, which traps solids in the exhaust stream. These solids, or particles, are carbon and ash. The filter will need to undergo a cleaning process called regeneration periodically to convert the carbon into carbon dioxide through exposure to high temperatures.

The gas then passes through the selective catalyst reduction system, which removes the oxides of nitrogen with the help of diesel exhaust fluid. There is also an exhaust gas recirculation valve, cooler and mixer in this system. All of this equipment is there to reduce harmful emissions.

Cooling System

The cooling system helps maintain proper engine temperature, which allows all of the parts to work correctly. It keeps oil and engine components at the right temperature, which in turn helps protect the cylinder head, cylinders, valves and pistons. There are two different types of cooling used in internal combustion engines: air cooling and water cooling. While gas engines can use either method, diesel engines use water cooling exclusively.

Electrical System

The electrical system is made up of the alternator, starter motor and battery. The starter motor, which is powered by the battery, rotates the flywheel, which rotates the crankshaft. This is what causes the pistons to move in the cylinders. The piston c

No comments